|

When you’re in a work zone, you and your co-workers put your lives on the line. Staying safe out there is a group effort. You watch out for each other and try to maintain a safe environment. But workers make common, everyday mistakes that can go unnoticed. Through staged photography, this article gives some examples of real scenarios where workers are putting themselves at risk.

The No. 1 accident that is most likely to occur, and probably the most serious of all, is injuring the dump person. This person is |

|

Hitching a

ride is a dangerous practice. In the photo at left, the backhoe operator appears to be driving at about 30 miles (48 km) per hour with a co-worker riding on the side of the machine. ride is a dangerous practice. In the photo at left, the backhoe operator appears to be driving at about 30 miles (48 km) per hour with a co-worker riding on the side of the machine.  This unsafe practice could result in the "passenger’s" death if they hit a bump in the road. In the photo below left, the worker is riding in this unsafe position to the area where the traffic cones will be placed. Workers may think hitching a ride on truck beds or one-person machinery saves time in getting from point A to point B, but any time saved is lost when the crew has to stop for an accident. Notice also that the person "hitching a ride" in the photo above, at right, is also missing a hard hat. Because he is standing where the operator cannot see him, the operator would not know if his "passenger" fell off the machine. The rider faces the possibility of head injury and getting run over by th This unsafe practice could result in the "passenger’s" death if they hit a bump in the road. In the photo below left, the worker is riding in this unsafe position to the area where the traffic cones will be placed. Workers may think hitching a ride on truck beds or one-person machinery saves time in getting from point A to point B, but any time saved is lost when the crew has to stop for an accident. Notice also that the person "hitching a ride" in the photo above, at right, is also missing a hard hat. Because he is standing where the operator cannot see him, the operator would not know if his "passenger" fell off the machine. The rider faces the possibility of head injury and getting run over by th e machine he’s on. A good rule of thumb to remember when riding on a piece of equipment is to always wear your seatbelt. If you don’t have a seatbelt, or a seat, you should not be on the machine while it is operating. e machine he’s on. A good rule of thumb to remember when riding on a piece of equipment is to always wear your seatbelt. If you don’t have a seatbelt, or a seat, you should not be on the machine while it is operating. |

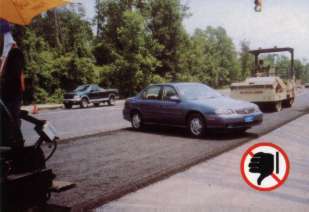

In the photo at right, the operator can control only one of the safety problems before him. As discussed above, he should not allow his co-worker to ride along on the machine without a seat or a seatbelt. The situation the roller operator can’t control is that of John Q. Public driving across the paving lane. In this situation, the motorist scooted out of a parking lot ahead of the roller. Sometimes it seems the traffic control crew can set up a cone every three feet and the motoring public would still try to squeeze between them. The best a crew can do is try to create a simple traffic management situation and sign it heavily. Notice in the photo below left that the motorist has gotten into a very dangerous situation. The screed operator, roller operator and lute man all have their backs turned. The motorist appears to be running a red light and is driving across an uncompacted mat. While the crew cannot guess ever In the photo at right, the operator can control only one of the safety problems before him. As discussed above, he should not allow his co-worker to ride along on the machine without a seat or a seatbelt. The situation the roller operator can’t control is that of John Q. Public driving across the paving lane. In this situation, the motorist scooted out of a parking lot ahead of the roller. Sometimes it seems the traffic control crew can set up a cone every three feet and the motoring public would still try to squeeze between them. The best a crew can do is try to create a simple traffic management situation and sign it heavily. Notice in the photo below left that the motorist has gotten into a very dangerous situation. The screed operator, roller operator and lute man all have their backs turned. The motorist appears to be running a red light and is driving across an uncompacted mat. While the crew cannot guess ever ything motorists will do, safety demands each member stay aware of their surroundings. (All photos were staged to illustrate unsafe practices.) ything motorists will do, safety demands each member stay aware of their surroundings. (All photos were staged to illustrate unsafe practices.)

|

|

Don’t forget about the peripheral crew members

when you’re watching out for your co-workers’ safety. The striping crew needs the same attention and protection that the paving crew needs. In this instance, the striping crew appears to be alone (at right). Neither worker has a safety vest or hard hat. They bring up the rear of this manufactured scene, with no attenuators or protective vehicles of any kind to protect them from a stray vehicle entering the work zone. Make sure you don’t forget about the very back end of the job site when protecting workers. when you’re watching out for your co-workers’ safety. The striping crew needs the same attention and protection that the paving crew needs. In this instance, the striping crew appears to be alone (at right). Neither worker has a safety vest or hard hat. They bring up the rear of this manufactured scene, with no attenuators or protective vehicles of any kind to protect them from a stray vehicle entering the work zone. Make sure you don’t forget about the very back end of the job site when protecting workers.Quality Control / Quality Assurance (QC / QA) workers can be in peril as well. This gentleman poses with his back to the traffic lane (below). He is checking the density of the pavement, but will not know if a car is  headed his way until it’s too late. Because he is the sole operator of the truck in the photo, he can be assured of safety from being backed over by locking out and tagging out the vehicle. Notice that the truck has strobe and flashing lights attached for safety. headed his way until it’s too late. Because he is the sole operator of the truck in the photo, he can be assured of safety from being backed over by locking out and tagging out the vehicle. Notice that the truck has strobe and flashing lights attached for safety. In the lower photo at right, two truck drivers demonstrate the unsafe practice of meandering around the paving site without safety vests, hard hats, proper work shoes or proper work clothing. Even truck drivers must be made to understand that the material they ship is hot enough to cause serious burns to their skin. In this photo, the drivers are also walking with their backs to the paving train, which could spell trouble if a roller operator is not aware that they are out of their trucks and in the paving lane. In the lower photo at right, two truck drivers demonstrate the unsafe practice of meandering around the paving site without safety vests, hard hats, proper work shoes or proper work clothing. Even truck drivers must be made to understand that the material they ship is hot enough to cause serious burns to their skin. In this photo, the drivers are also walking with their backs to the paving train, which could spell trouble if a roller operator is not aware that they are out of their trucks and in the paving lane. |

The tack truck operator should never try to adjust the controls from outside the truck. In this instance, the worker is showing how being in a hurry can set you up for an accident (below). The proper way to adjust the computer in the tack truck is to open the door, climb inside, sit in the seat and face the computer. Then you can properly, and safely, set the controls for the rate of spray. The photo at right shows a lone tack The tack truck operator should never try to adjust the controls from outside the truck. In this instance, the worker is showing how being in a hurry can set you up for an accident (below). The proper way to adjust the computer in the tack truck is to open the door, climb inside, sit in the seat and face the computer. Then you can properly, and safely, set the controls for the rate of spray. The photo at right shows a lone tacktruck operator lighting the burners.  Whenever the tack truck operator is starting operation, another worker should be nearby to keep an eye on him or her. The buddy system can prove to be a life saver if something should go wrong with the propane tank by the man’s right hand or the hoses of hot liquid behind him. Whenever the tack truck operator is starting operation, another worker should be nearby to keep an eye on him or her. The buddy system can prove to be a life saver if something should go wrong with the propane tank by the man’s right hand or the hoses of hot liquid behind him. |

In these photos, the roller operator is facing away, from the woman who is standing between the roller's body and drum. She could easily lose her life in this situation. Workers should never step behind the roller's drum. There is no reason to be in this position while the roller is on. If the operator turns the steering wheel to the left (at left), the woman will be crushed. Even in the photo at right, where the woman is trying to point something out to the driver, she has no business being in that position. This hazard is not a reflection on the machine itself, but on the practices of the workers around it. Use caution and good judgment when near heavy machinery, and never stand between the drums of an articulated roller. In these photos, the roller operator is facing away, from the woman who is standing between the roller's body and drum. She could easily lose her life in this situation. Workers should never step behind the roller's drum. There is no reason to be in this position while the roller is on. If the operator turns the steering wheel to the left (at left), the woman will be crushed. Even in the photo at right, where the woman is trying to point something out to the driver, she has no business being in that position. This hazard is not a reflection on the machine itself, but on the practices of the workers around it. Use caution and good judgment when near heavy machinery, and never stand between the drums of an articulated roller. |

In these photos, the crews are demonstrating proper handwork and traffic control safety. Everybody has their hard hats on, but not every crew member is wearing the hat correctly. Make sure hats are worn with the front facing forward. Everybody has their safety vests on. The motoring public will approach these work zones and notice that something is going on. The passerby cannot help but see all the safety orange in these scenes. In these photos, the crews are demonstrating proper handwork and traffic control safety. Everybody has their hard hats on, but not every crew member is wearing the hat correctly. Make sure hats are worn with the front facing forward. Everybody has their safety vests on. The motoring public will approach these work zones and notice that something is going on. The passerby cannot help but see all the safety orange in these scenes.

Proper traffic control and work zone setup is the first step in protecting the crew. But drivers today are in a hurry. They are easily confused by the flashing lights, activity and orange cones of a construction zone. No matter how hard the flaggers and crew try to keep cars out, some motorists may be distrac |

Above a safe paving crew makes its way down the paving lane. The safety light is on the paver. Everybody is wearing their safety vests. One person has removed his hard hat to scratch an itch, but overall, the crew seems to be aware of the important elements for keeping themselves protected. Even the seated workers are facing the right direction to keep an eye on the mat and on approaching traffic. The motoring public has a clearly defined work zone and evenly spaced safety cones. Keep safety on your mind Also, taking responsibility for your own safety, goes a long way toward keeping, you alive in a work zone. Don't set your safety vest or hard hat to the side because it's a hot day. Take advantage of every, safety apparatus you can, like steel-toed shoes, safety vests, hard hats, wide reflective bands on vests and hats. The more visible you are, the better your chances are of coming home with all your parts in tact at night. When drivers get distracted or lean over to change the radio station, that extra-wide band of reflective tape may be the one thing they catch out of the corner of their eyes to alert them to danger. If the driver sees the hat or the vest out of the corner of his or her eye, it could save your life. All in all, as we go paving down USA Highway # I, we've got to watch out for one another. One accident can cripple a company. One accident can snuff you out. Learn from near misses and keep them from becoming accidents. Remember, safety is for life ... yours! |

Top Quality Paving PO Box 4398 Write to us at our E-mail address for more information Visit Asphalt Contractor Magazine Online! WebMaster: Sullivan+Wolf Design, LLC |

in charge of "cleaning" the hopper between dumps. He or she is the one who reaches in with a long-handled shovel to manipulate material (below left). This person is also responsible for manipulating the excess mix to the center of the paving lane, out of the paver’s tracks, when the trucks pull away (below right). This person must stay aware of his or her surroundings, and truck drivers need to keep track of where this person is. In the photo in the right-hand corner, the dump man is in the truck driver’s blind spot, shoveling mix. If the driver needed to back up to release the mud flaps from the back wheels, the dump man would be hit and injured. To avoid injury in these situations, make sure all backup alarms are functioning properly, and have truck drivers stay, aware of the dump person’s position at all times. If your truck driver does not know where the dump person is, he or she should not back up. Make sure your truck drivers are aware of this danger.

in charge of "cleaning" the hopper between dumps. He or she is the one who reaches in with a long-handled shovel to manipulate material (below left). This person is also responsible for manipulating the excess mix to the center of the paving lane, out of the paver’s tracks, when the trucks pull away (below right). This person must stay aware of his or her surroundings, and truck drivers need to keep track of where this person is. In the photo in the right-hand corner, the dump man is in the truck driver’s blind spot, shoveling mix. If the driver needed to back up to release the mud flaps from the back wheels, the dump man would be hit and injured. To avoid injury in these situations, make sure all backup alarms are functioning properly, and have truck drivers stay, aware of the dump person’s position at all times. If your truck driver does not know where the dump person is, he or she should not back up. Make sure your truck drivers are aware of this danger.

ted or confused enough to enter the work zone. Some traffic coordinators have the luxury of a follow car at the paving site. This is a vehicle that drives past the work zone, leading the motoring public along the safest path. When motorists see this vehicle with its flashing, blinking lights and clear "follow me" lettering, they know exactly what it is for.

ted or confused enough to enter the work zone. Some traffic coordinators have the luxury of a follow car at the paving site. This is a vehicle that drives past the work zone, leading the motoring public along the safest path. When motorists see this vehicle with its flashing, blinking lights and clear "follow me" lettering, they know exactly what it is for.